Scarab 18 foot folding trimaran

We built two of these boats Both of them were built using foam sandwich construction. The panels were made by joining the foam sheets together the full length of the boat and then covering with glass. Building a foam sandwich flat panel boat is similar to building a boat in plywood. Covering the panel with peel ply makes it smooth so it is easier to fill the boat.

We make our own foam sandwich panels. If you have space it is good to make them the length of the boat.

The main-hull is lifted off the frame and turned over. This boat was designed with a flat panel on the bottom so it can be rest on a piece of plywood or carpet on the floor eliminating an extra building frame. It also makes the boat low enough so it is easy to work inside. The joints were filleted and taped.

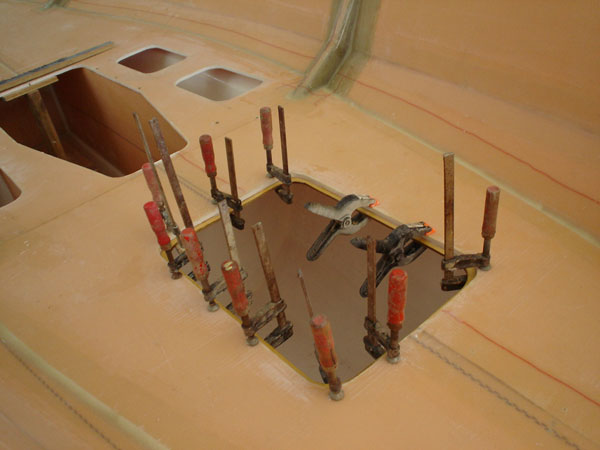

The next job to complete on this boat is the beam supports that hold the forward and aft beams. To make these beams foam is cut to the right shape and layers of foam are glued together. Many layers of glass are added to the foam shapes until all the laminates stipulated in the plans are added. The edges are smoothed off (a sanding disc in a grinder works well). Double bias tape is added to the edges to hold all the foam and glass together. The pivot holes for the folding system are drilled at this time. It is easier to drill plumb holes at this stage. A drill press, if available, works well.